About

|

In 1975, Andy Chisholm started making printed circuit boards (PCB’s) at his home in Cape Town. As his list of customers grew, so did his need for staff and working space. After forming a company called RENAK, he moved to Gabriel House in Plumstead and later, to the Diel Building in Estmil Road Diep River. As time went by, quality became more important and the demand for PCB’s increased, as did the need for capital to allow the latest processes to be installed.

|

In 1983, Andy made a deal with Plessey South Africa for a phased buy-out of shares from himself and his partners. This was followed by a move to larger premises in Estmil Road. Plessey completed the share buy-out in 1986 and from then until early 1991, they expanded RENAK and introduced new processes. These included multilayer PCB’s, hot air solder levelling and photo-imageable solder masks. During this period, Renak bought its main competitor, Alumet Circuit Technologies in Johannesburg and moved the Alumet plant to Cape Town. Their processes and customers were integrated with those of Renak and the combined operation was renamed Renak Alumet Circuits.

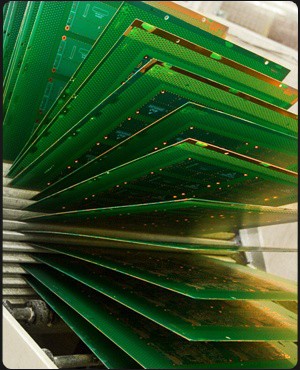

In 1990, government and S A Post Office order reductions made Plessey decide to close Renak Alumet Circuits, leaving a real opportunity for enterprising businessmen. In late 1991, Andy Chisholm, Dave Delbridge and Viv James formed TraX Interconnect and purchased the assets of Renak Alumet Circuits from Plessey South Africa. They were able to lease the Estmil Road factory, hire a core group of original Renak Alumet employees and re-open the plant to make small to medium runs of high quality PCB’s for on time delivery to their customers. In the intervening years to the present TraX has come to employ 80 people and maintained steady growth in terms of both technology and capacity. Currently the company is capable of producing 10 layer PCB’s with track width and spacing at an impressive 0.15mm and finished hole sizes of 0.2mm. |

These capabilities have only come about through the decision to reinvest a sizable portion of profits in new technology, which has kept TraX at the forefront of the local industry. TraX counts the market leaders of the South African electronics industry as its customers and will continue to service their needs. These customers are in diverse sectors of the market covering the defence, telecommunications, data acquisition, security and medical fields. A host of these customers are multinationals operating in South Africa so they export a significant portion of our populated board.

In order to meet the stringent quality standards of these customers TraX was the first PCB manufacturer in the country to be awarded the ISO 9001:2000 certification by the South African Bureau of Standards (SABS) and is the only manufacturer in the country certified to use the UL mark on its products. Although TraX is not a large company, we offer real value and service in what we set out to do, namely, manufacture small to medium runs of high quality PCB’s for on time delivery to our customers. This philosophy is what we hope will ensure our continued growth and development through the current worldwide PCB rationalisation. The fact that our currency and labour are relatively inexpensive when compared to the major economies should also be considered. A look around these pages will give you a good idea of our capabilities. |